A Cylinder Leak Down Test is similar to an engine compression test … but in reverse! You use compressed air to pressurize each cylinder and then listen for air escaping from various “listening points”. This approach gives better clues to where a problem lies.

This post contains affiliate links or sponsored content. See my Disclosure Policy for more details.

Equipment

One of the attractions of compression testing is that all you require is compression tester and about 20 or 30 minutes.

For a cylinder leak down test, you need a cylinder leak down tester (no surprise there), an air compressor and about 45 minutes.

Preparation

- Ensure that you have the correct equipment. I have a cheap, eBay cylinder leak down tester which, although it works ok, I probably wouldn’t recommend.

- Run the engine up to normal working temperature; about 10 – 15 minutes. You can do the leak down test cold if the engine cannot be run, but the results will not be as reliable.

- Disconnect the battery

- Label all of your spark plug leads before removing them to ensure that you can refit them in the correct order

- Clean around the spark plug insets to prevent dirt and grit from getting into the cylinders. Use your airline; this will be the best way to clear the area (don’t forget your safety goggles !)

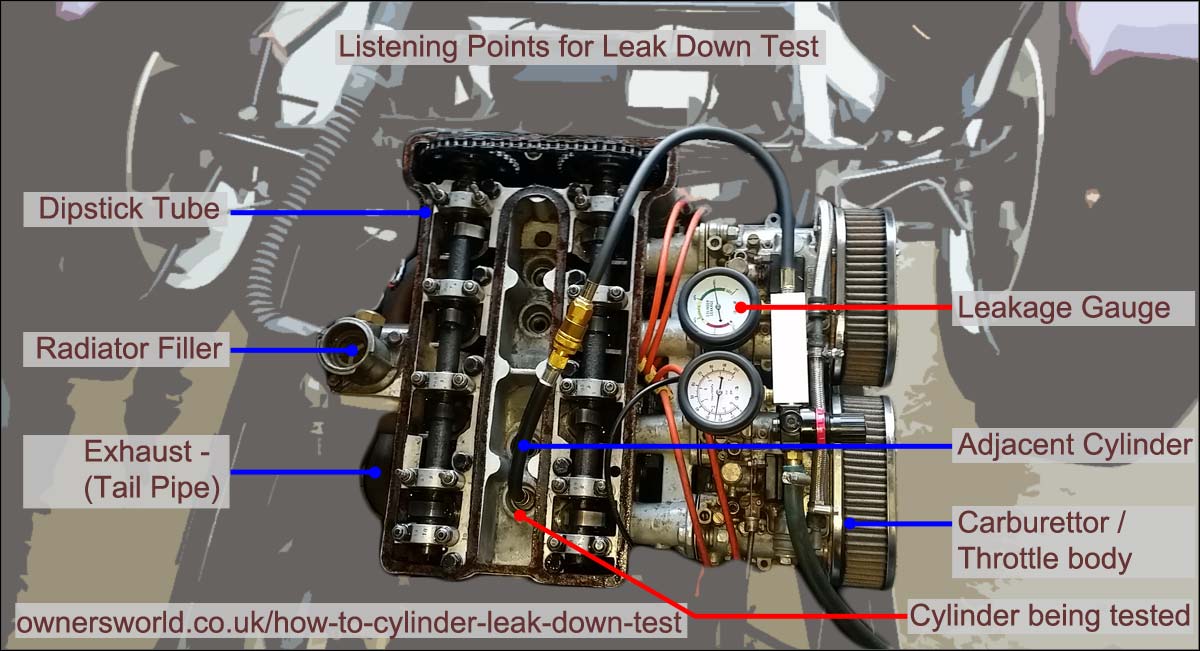

- Remove: all spark plugs; engine oil dipstick; radiator filler cap; carburettor air filters or fuel injection throttle body filter.

These are the points where you will listen for air escaping during the leak down test. - Remove the valve cover so that you can see when both inlet and exhaust valves are closed.

- Turn off the regulator on the tester and then connect it to the air supply. (If you don’t turn off the regulator, you run the risk of damaging the gauges on the tester)

disclaimer

The information contained herein is not meant to be comprehensive and is for information and entertainment purposes only.

You should not undertake to perform anything described herein without adequate training and/or supervision.

The author disclaims any responsibility for any injury, damage, or loss as a result of reliance upon the

information found on this site/blog.

Please see Terms for more details.

Carry out the cylinder leak down test

Each model of tester will have its own set of instructions but they all follow a similar approach.

Follow these steps for each cylinder (it is quicker and easier to carry out the leak down test on the cylinders in their firing order sequence)

- Bring the piston up to top dead centre on the compression stroke (inlet and exhaust valves closed).

- Screw the tester adapter hose into the spark plug hole.

- Calibrate the tester. (more information about calibrating the tester at the end of this article)

- Connect the tester to the adapter hose. On my tester, this is the method for introducing the calibrated compressed air into the cylinder. Yours may work differently; check your instructions.

- After about 30 seconds, the reading should stabilize. Make a note of the leakage for that cylinder.

- Listen for air escaping at all of the listening points and make a note if you hear anything. See the diagram below. You can use a clean length of pipe or a mechanics stethoscope (with the probe removed) to help.

Listen to the pitch of the leakage. If it is high pitched, then the leakage is low. If it low pitched, then the leakage is high.

The cylinder leak down test is now complete, so put your car back together (spark plugs, radiator cap etc) and interpret your results.

Interpreting the results

Leakage gauge reading

Firstly, the readings from the leakage gauge for each cylinder indicate how gas-tight the cylinder is. All cylinders, even in tip-top condition, have some leakage past the rings, especially if the engine is cold. The instructions for my cylinder leak down tester say that any leakage under 20% is considered as “non-leaking”. All cylinders should be within 15% of one another.

Any leakage over 40% and you are probably looking at an engine overhaul in the near future. Once you get to 60% leakage, then it’s time to get the spanners and the cheque book out!

If you’re seeing very high leakage, make sure that you have positioned the engine at top dead centre on the compression stroke and not the exhaust stroke. On the exhaust stroke, the exhaust valves are open. Obviously, if you are on the compression stroke, it could be that you have broken rings or a very badly scored cylinder wall!

It’s worth noting that, typically, large engines tend to leak more than small engines.

Listening points

Secondly, review your notes about leakage at the listening points against the bullets below.

- Oil dipstick tube – Indicates damaged cylinder wall or piston rings

- Radiator filler – Indicates cylinder wall cracks or head gasket leakage

- Adjacent cylinder – Indicates cylinder wall cracks or head gasket leakage

- Exhaust tailpipe – Indicates leaking exhaust valve

- Carburettor / Throttle body – Indicates leaking inlet valve

The dynamic (and static) duo

Compression testing is a dynamic test; pistons going up and down, valve train opening and closing. You measure how much pressure the cylinder can produce.

A cylinder leak down test is a static test; You set the engine to a specific state and then measure how much pressure the cylinder can maintain.

If you combine the results from both tests, you can get even further insights.

If a SINGLE cylinder has low compression, but low leakage, this normally indicates that there is a problem in the valvetrain for that cylinder. Possibly a broken valve spring, bent push rod or worn cam lobe.

if ALL the cylinders have low compression, but low leakage, this normally indicates incorrect valve timing (which is why it impacts all the cylinders). Provided that you are not going to do serious damage to the engine, try carrying out a vacuum test to confirm incorrect valve timing.

Calibration

Just a little bit about calibrating a cylinder leak down tester. The idea behind calibration is to regulate the pressure coming from your air compressor such that, if the tester is connected to a perfectly airtight cylinder, the reading on the leakage gauge will be exactly zero (not more and not less). If the cylinder is not airtight, then air leaks out of the cylinder and the reduced pressure reads as a percentage leakage on the gauge. You therefore need to keep the compressor attached to the tester for the duration of each test to maintain the supply pressure.

Just a final point to consider is that there are no industry standards for cylinder leak down testers for cars. As such, it is not possible to do a direct comparison between the results from different testers.

Summary

A cylinder leak down test is a great follow up to compression testing for getting a more specific diagnosis. Although the test should be done on a warm engine to get the best results, you can do it on a cold, non-running engine to give a view on its condition. This is useful if you think that running the engine will cause damage, or the engine is not connected up for running.

If you have any further tips or recommendations for performing a cylinder leak down test, please let me know in the comments below and I may include them in the next revision of this article.

Excellent Steve, I’ve done plenty of compression tests in the past but hadn’t heard of leak down testing. I’m sure it would have identified the broken piston ring in my K Series quickly 🙂 I’ll do the test when the engine is rebuild to A; ensure that the repairs have been successful and b; to give me a baseline for future tests.

Thanks Phil. It was recommended to me by a chap on the Facebook group Caterham Techtalk. It’s pretty simple to do and would have saved me a great deal of heartache in diagnosing a jammed inlet valve on my Lotus Twin Cam if I’d known about it earlier!